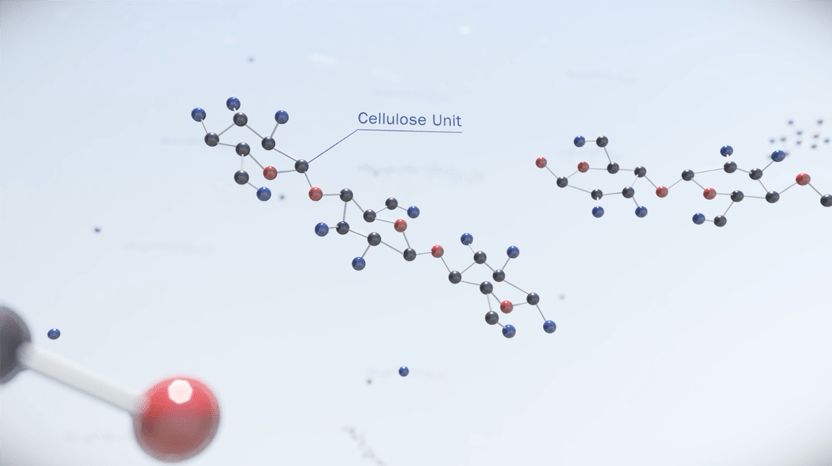

Hydroxypropyl methyl cellulose (HPMC) is a non-ionic cellulose ether. It is odorless, tasteless, off white powder, can be dissolved in water and forms transparent viscous solution. HPMC is widely used in building materials, ceramic extrusions, personal-care products and many other fields, It will improve your products in water retention, bonding ability, thickening effects, dispersion rate and suspension etc.

Lubrication

Improves workability and processing effect of cement-based and ceramic-based extrusions by its lubrication.

PH stability

Matecel® remains stable in the range of pH 3.0~11.0. The solubility of Matecel® can largely increase in the presence of alkali environment.

Stable Chemistry

Compatible with other ionic and non-ionic additives in aqueous solutions while providing a stable combination when dissolved in water.

Save Cost

Large water demand of Matecel® can make your materials yield higher volume of outputs, and thus save your cost.

Thickening effects

Matecel® Increases viscosity of liquids in daily-chemical products and personal care products

Suspension effects

Enhances dispersion rate suspension effect and the stability of suspension systems, including concrete, mortar, EIFS system.

Water retention

Avoid quick water-loss during the drying of constructions, enhance water retention, ensure sufficient hydration time for cement-based, lime-based and gypsum-based materials.

Open time

Matecel® prolongs the open time during application, give more time for correction.

Lubrication

Improves workability and processing effect of cement-based and ceramic-based extrusions by its lubrication.

PH stability

Matecel® remains stable in the range of pH 3.0~11.0. The solubility of Matecel® can largely increase in the presence of alkali environment.

Stable Chemistry

Compatible with other ionic and non-ionic additives in aqueous solutions while providing a stable combination when dissolved in water.

Save Cost

Large water demand of Matecel® can make your materials yield higher volume of outputs, and thus save your cost.

Thickening effects

Matecel® Increases viscosity of liquids in daily-chemical products and personal care products

Suspension effects

Enhances dispersion rate suspension effect and the stability of suspension systems, including concrete, mortar, EIFS system.

Water retention

Avoid quick water-loss during the drying of constructions, enhance water retention, ensure sufficient hydration time for cement-based, lime-based and gypsum-based materials.

Open time

Matecel® prolongs the open time during application, give more time for correction.

Technical specification

| Item | Hydroxypropyl Methyl Cellulose |

|---|---|

| Methoxy (WT%) | 19.0-32.0 |

| Hydroxypropoxy (WT%) | 4.0-12.0 |

| Gelation temperature (˚C) | 60.0-75.0 |

| Viscosity (mPa.s) (2% solu., 20˚C) | A Complete viscosity range can be Customized |

| Loss on drying (%) | ≤5.0 |

| Ash | ≤5 |

| pH | 4.0-8.0 |

Application suggestions

| Grades | Application Scope | |||||||

| Self-leveling | CTA | Putty | General mortar | Gypsum plaster | Water-basedpaint | Daily chemicaldetergent | Ceramic&Cement extrusion | |

| MH401 | ||||||||

| PMK200Z | ||||||||

| PME100Z | ||||||||

| PME100ZS | ||||||||

| PME200ZS | ||||||||

| GMK150Z | ||||||||

| MH60Y | ||||||||

| Grades | Application Scope | |||

| Self-leveling | CTA | Putty | General mortar | |

| MH401 | ||||

| PMK200Z | ||||

| GMK150Z | ||||

| PME100Z | ||||

| —— | Gypsum plaster | Water-basedpaint | Daily Chemical detergent | Ceramic & Cementextrusion |

| PME100Z | ||||

| PME100ZS | ||||

| PME200ZS | ||||

| MH60Y | ||||

Mortar/Concrete /EIFS/ETICS

Mortar/Concrete /EIFS/ETICS

Matecel cellulose gives the following excellent properties of dry-mix and ready-mixed mortar:

Excellent water retention rate

Smooth workability

Better Pumping

Provide sufficient cement hydration time

Give construction higher strength

Recommend:

Tile Adhesive

Tile Adhesive

For different methods of binder, Matecel can provide various cellulose ether products to easily meet different requirements.

Advanced workability

High water demand and high output

Excellent sag resistance

Prolonged open time

Easy to spread out and not sticking to knife

Recommend:

Renders / Plasters / Skim Coat

Renders / Plasters / Skim Coat

Cement-based RendersCement based jointing and trowelling compounds are used for repairing systems and to smooth coarse walls and floors. Grouts are applied to fill the gaps between ceramic or stone tiles.

Recommend:

Gypsum shows excellent fire resistance but it’s not water resistant, therefore gypsum plasters are widely used for internal walls.

The main applications for gypsum-based construction materials are plasters (hand or machine applied), troweling compounds, joint fillers and adhesives.

With machine applied plasters, an efficient covering of large walls and ceiling areas is possible.

Recommend:

Skim coat with Matecel® offers smooth wall surface. Bring easy workability, long pot life, excellent water retention and more.

Recommend:

Painting

Painting

Matecel® can be used in water-based paints, with excellent emulsification effect, dispersion rate, stability and water retention. It will help paintings and coatings to achieve better rheological property at different shear rates, so your products enjoy smooth leveling, good anti-peeling and slip resistance.

Good enzyme resistance

Smooth leveling and flow

Advanced thickening ability

Improve suspension rate

Recommend:

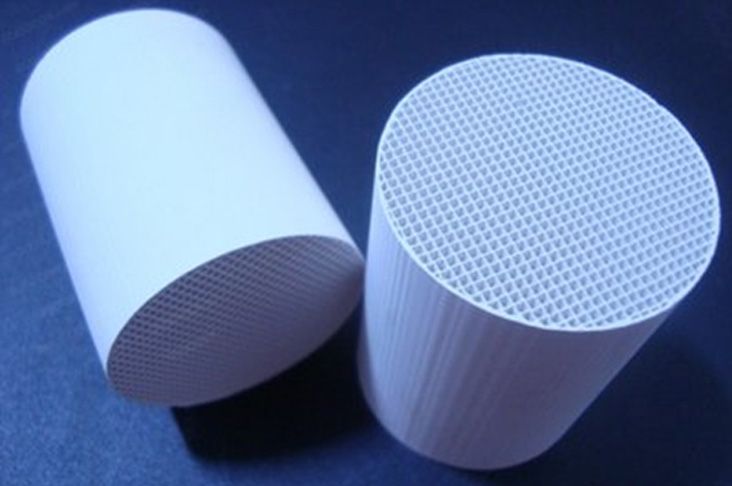

Ceramic Extrusion

Ceramic Extrusion

Matecel® can be used as plasticizer in Ceramic Extrusion. It can fasten hydration speed and increase expansion index of the ceramic.

Good lubrication, conducive to extrusion molding

Improve the strength of ceramic

Adjust the viscosity of glaze, so it has good rheology, easy to apply

Enhance the bonding ability ceramic surface and glaze so surface is smoother

Recommend:

Home Care & Personal Care

Home Care & Personal Care

Home Care ProductsHome Care products include all types of liquid products such as floor cleaners, detergents and dish washing products with pH between 4 - 11

Matecel can be used as a thickener to adjust the rheology of liquid detergents, adjust to desired appearance and ideal consistency.

Matecel enables viscous formulas and gel cleaners be extra useful and more favorable, because Matecel will let gel cleaners left on the surface and work for an extended period of time, so better cleaning result.

Thickening effects

Adjustment of consistency

Compatibility with ionic surfactants

Solutions of high transparency

Recommend:

Matecel can give good thickening effect to personal care products including Nurturing cosmetics (hair care, skin care and oral hygienea) and Decorative cosmetics (make-up, powders, eye shadow and mascara).

Matecel improves the foam stability of shaving foams, increases the stickiness of adhesive creams.

Matecel acts as a binder in powder make-ups, and eases the distribution of hair colouring agents.

Thickening effects

Adjustment of consistency

Stabilisation

Solutions of good clarity

Recommend:

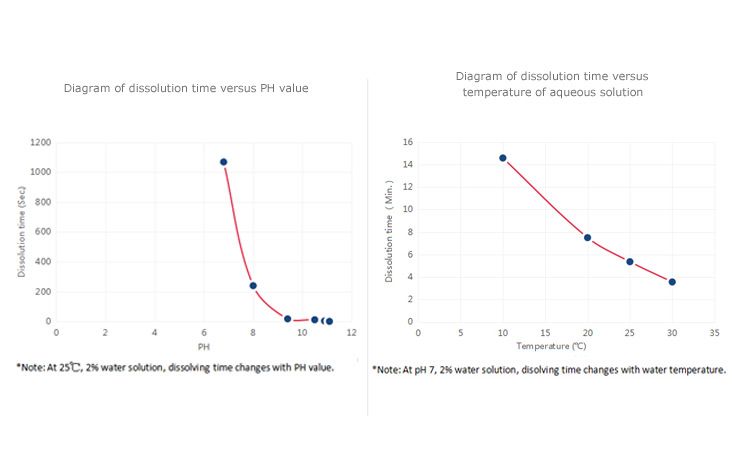

The dissolution time of HPMC in water (viscosity onset time from HPMC is put into water until the solution begins to thicken ) is mainly affected by the temperature and PH value of the aqueous solution.

The dissolution time is inversely proportional to PH. The greater the PH value is, the shorter the dissolution time will be.

The dissolution time is inversely proportional to the temperature of the aqueous solution. The higher the water temperature is, the shorter the dissolution time will be.

Recommend:

Self Leveling

Self Leveling

Self leveling mortar can rely on its own weight to form a flat, smooth and solid foundation on the substrate, so as to lay or bond other materials, and can carry out large-area and efficient construction. Therefore, high fluidity is a very significant feature of self leveling mortar; In addition, it must also have a certain water retention and bonding strength, do not produce water separation, and have the characteristics of heat insulation and low temperature rise.

High dispersion

Low viscosity

Wide adaptability to different self leveling formulation systems

Recommend:

REAL-TIME PRICE OF RAM MATERIALS

VISCOSITY CONVERSION

Package Information

| Item | Specification |

| Size | 850mm*600mm*100mm |

| Weight | 25 KG/Bag |

| Corlor | Blue, White, Yellow |

| Storage | Dry and clean conditions |

We can also customize your packages!

Shijiazhuang Henggu Jianxin Cellulose Co.,Ltd is a reputable and leading factory in the field of cellulose ether products, specializing in meeting the changing needs of the construction industry. Our expertise distinguishes itself by supplying top-tier Hydroxypropyl Methyl Cellulose (HPMC) products that consistently meet the industry's demands for quality and innovation. With an impressive 18-year legacy, we have an unparalleled understanding of the complexities and nuances of the field.

Hydroxypropyl methylcellulose (HPMC) is a synthetic compound derived from cellulose, a natural plant polymer. Manufactured through chemical modification, hydroxypropyl methylcellulose is water-soluble and versatile, finding applications in various industries. It is used as a thickening and gelling agent in cosmetics, food and pharmaceuticals, while also forming flexible films for drug coating and controlled release. Hydroxypropyl methylcellulose stabilizes the texture of foods, delays the crystallization of sugar in confectionery and acts as a non-ionic safe ingredient. Its compatibility with various compounds, temperature and pH tolerance, and use in construction materials make it an important component in enhancing the performance of products from tablets to construction materials.

(1)Water Solubility: HPMC is soluble in water and forms a clear and viscous solution when mixed with water. Solubility can be tuned by varying the degree of substitution (DS) and molecular weight of the polymer.

(2)Viscosity Control: HPMC is commonly used as a thickening and gelling agent in a variety of products including cosmetics, food and pharmaceuticals. Its viscosity can be controlled by adjusting its concentration in the solution.

(3)Binder: In the pharmaceutical industry, HPMC is used as a binder in tablet formulations. It helps hold the active ingredients together and ensures the integrity of the tablet.

(4)Controlled release: HPMC is used to control the release of active ingredients in pharmaceutical formulations. Depending on its properties, it can provide sustained or delayed release of the drug.

(5)Stabilizers: In food, HPMC acts as a stabilizer, helping to maintain the texture and consistency of a variety of foods including sauces, dressings and desserts.

(6)Temperature and pH tolerance: HPMC maintains its properties at a wide range of temperature and pH levels, making it suitable for a wide variety of applications.

(7)Construction: In the construction industry, HPMC is used as a thickener, water retaining agent and binder in cement-based products. It improves the adhesion, workability and overall performance of building materials.

What sets us apart is not only our obsession with quality, but also our commitment to customizing the customer experience. Recognizing the diverse financial environment, we offer flexible payment terms, ensuring our products are available to a wide range of partners. Additionally, we believe in tangible experiences, which is why we offer our customers the opportunity to request free samples. This not only demonstrates the exceptional quality of our products, but also reinforces our transparency and customer-centric approach.

Our proud 98% customer approval rate is a testament to our exceptional quality. This resounding vote of confidence speaks volumes about our unwavering commitment to delivering products that exceed expectations.

We map the strategic trajectory and invite agents, large distributors and end customers to interact with us. By working with these esteemed partners, we aim not only to provide service, but also to foster lasting relationships that further drive the industry forward.

Shijiazhuang Henggu Jianxin Cellulose Co., Ltd. can provide high-quality HPMC and is committed to shaping the future of building materials through HPMC innovation.

Hydroxypropyl methylcellulose (HPMC) is a cellulose ether in which the hydroxyl groups on the cellulose chain are replaced by methoxy or hydroxypropyl groups. HPMC is used as a thickener, adhesive and film former in agrochemicals, coatings, ceramics, adhesives, inks and a variety of other applications. The aqueous solution of HPMC undergoes reversible gelation when heated, thereby controllably increasing the green strength of the green ceramic body.

HPMC is the abbreviation of hydroxypropyl methylcellulose. It is a dissolving agent commonly used in pharmaceutical, food, construction and cosmetics fields. Overall, HPMC is generally considered safe and is widely used in many applications.

However, safety depends on use, dosage and individual differences. In the pharmaceutical and food industries, products using HPMC are often subject to necessary safety assessment and supervision. If you have safety concerns about HPMC for a specific use or product, it is best to consult the relevant scientific literature or consult a professional.

HPMC, as a polymer, has shown good properties in many applications, but it also has some shortcomings. HPMC is a soluble dye in cold water and requires a certain temperature to fully dissolve. Thermal stability of HPMC may be relatively low compared to other materials. In high temperature environments, it may cascade or lose some performance. The strength of HPMC may decrease in dry environments, which may impact some applications requiring moisturizing strength.

Why is it important to add hpmc to tile adhesive?

HPMC can improve product functionality very well, and is now widely used in the construction industry, especially in tile adhesives.

HPMC Uses in Construction: Enhancing Building Materials and Performance with Versatile Properties

HPMC Uses in Construction: Enhancing Building Materials and Performance with Versatile Properties HPMC (Hydroxypropyl Methyl Cellulose) is a versatile polymer that finds extensive use in the construction industry. It is a non-ionic cellulose ether that is derived from natural cellulose. HPMC is widely used in the construction industry due to

The Role of HPMC in Tile Adhesive: Enhancing Slip Resistance, Flexural Strength, and Bonding Performance

The application of HPMC in tile adhesive brings about a range of significant benefits. Its inclusion enhances slip resistance, promoting increased safety and durability for tile installations. Furthermore, HPMC improves the flexural performance of the adhesive by mitigating the risks of cracking and detachment caused by environmental factors. Addit

Application of HPMC in Building Materials

The utilization of hydroxypropyl methyl cellulose (HPMC) in building materials is notable despite its small dosage, typically ranging from 0.1% to 1%. However, its impact is significant as it serves various purposes such as a plasticizer, water-retaining agent, air-entraining agent, and retarder in coatings, gray paste, mortar, and cement products.

LEAVE A MESSAGE

Shijiazhuang Henggu Jianxin Cellulose Co., Ltd.

Chemical Industrial Park, Xinji City, Hebei Province, China Post Code: 052360

Copyright 2023 Shijiazhuang Henggu Jianxin Cellulose Co., Ltd. All Rights Reserved