Jul. 04, 2023

1. Surface Treated HPMC (Delayed Solubility/Hydration HPMC):

Surface treated HPMC undergoes a cross-linking process during production, resulting in delayed solubility and hydration.

When added to cold water, the surface treated HPMC quickly disperses but does not dissolve immediately. It requires agitation and time to fully dissolve, and the viscosity gradually increases.

This type of HPMC is commonly used in applications where controlled viscosity build-up is desired, such as detergent, water-based paint etc.

2. Non-Surface Treated HPMC:

Non-surface treated HPMC tends to clump when added to cold water but quickly disperses in hot water.

With sufficient stirring, the non-surface treated HPMC dissolves and the viscosity gradually increases until a transparent viscous colloid is formed.

This type of HPMC is commonly used in dry-mixed mortars, such as mortar and putty, where immediate viscosity build-up is desired upon adding water.

In applications like glue and paint, clumping may occur when using non-surface treated HPMC, requiring hot water or thorough stirring to dissolve the clumps.

In summary, surface treated HPMC offers delayed solubility and controlled viscosity build-up, making it suitable for various applications. Non-surface treated HPMC, on the other hand, requires hot water or sufficient stirring to disperse and achieve immediate viscosity. The choice between these types of HPMC depends on the specific requirements and characteristics desired for the intended application.

There are two types of HPMC with different dissolution characteristics: cold-water instant soluble (surface treated) and hot-soluble (non-surface treated).

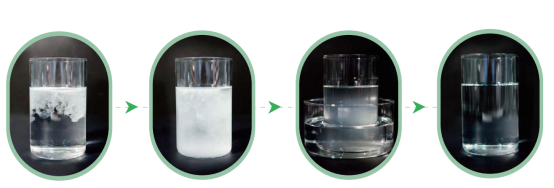

Cold-water instant soluble HPMC (surface treated) quickly disperses in cold water, but it does not dissolve immediately. As a result, the liquid initially has low viscosity. However, after approximately 2 minutes of stirring, the HPMC gradually dissolves, leading to an increase in viscosity. Eventually, a transparent viscous colloid is formed, indicating complete dissolution.

On the other hand, hot-soluble HPMC (non-surface treated) tends to form lumps when mixed with cold water. However, when combined with hot water, it disperses rapidly throughout the liquid. As the mixture is stirred and the temperature decreases, the viscosity slowly rises. Eventually, a transparent viscous colloid is formed.

In the case of cold-water instant soluble HPMC, the outer cellulose powder interacts with cold water, resulting in immediate viscosity and the formation of a transparent colloid. The cellulose inside, however, may remain in contact with the colloid or remain in a powdery state, slowly dissolving.

It is important to note that the perception that hot-water soluble HPMC solely relies on hot water is not entirely accurate. In practical applications, non-surface treated HPMC, commonly used in dry-mixed mortars like putty and mortar, does not require hot water for dissolution. When these dry powders are mixed with water, the cellulose particles become separated by other materials, leaving space between them. As a result, upon contact with water, the HPMC immediately becomes viscous, eliminating the formation of lumps.

Understanding these dissolving characteristics allows for the appropriate use of each type of HPMC in different applications, ensuring successful dissolution and preventing clumping or lumping.

If you want to know more information, welcome contact us or click to the website: https://www.hpmc.com/

Shijiazhuang Henggu Jianxin Cellulose Co., Ltd.

Chemical Industrial Park, Xinji City, Hebei Province, China Post Code: 052360

Copyright 2023 Shijiazhuang Henggu Jianxin Cellulose Co., Ltd. All Rights Reserved