Sodium carboxy methyl cellulose CMC is a water-soluble cellulose derivative, sometimes It is called "sodium salt". It is the most commonly used derivative of water-soluble cellulose derivatives and has high commercial value.

CMC is widely used in food, toothpaste, papermaking, ceramics, printing and dyeing, oil drilling and other industries.

Matecel® CMC Features:

Decrease the fluidity of the liquid

Increase the suspension of solids in aqueous solutions

Good film-forming properties

Good adhesive

Matecel® Application:

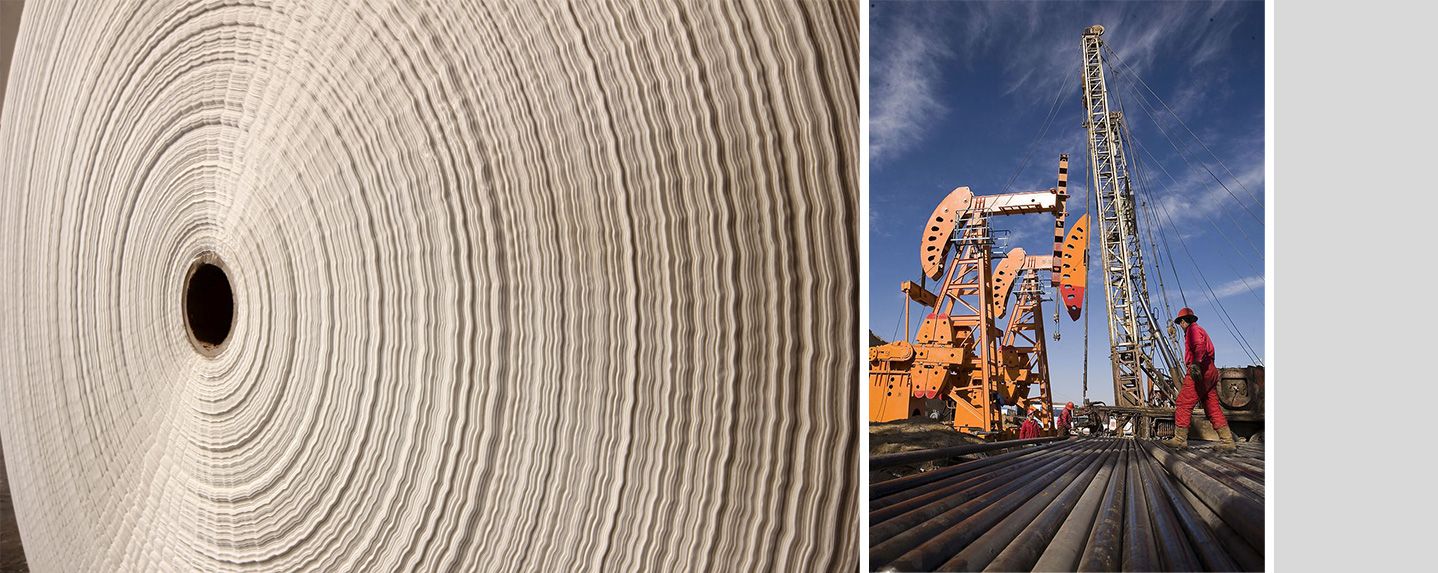

Matecel® CMC Papermaking Grade:

Matecel® CMC for ceramics:

Matecel® CMC is used in detergents:

Matecel® CMC for oil extraction:

Sodium Carboxymethyl Cellulose (CMC) is highly valued for its ability to modify viscosity, stabilize emulsions, improve texture, and enhance the binding properties of products across multiple industries, including food, pharmaceuticals, personal care, industrial applications, oil and gas, detergents, and more.

● Thickener: Improves the viscosity and texture of sauces, dressings, soups, and ice creams.

● Stabilizer: Prevents ingredient separation in products like salad dressings and beverages.

● Binder: Enhances water retention, texture, and shelf life in bakery products.

● Suspending Agent: Keeps ingredients suspended in drinks, syrups, and other liquid formulations.

● Binder and Filler: Ensures tablets hold together and release active ingredients properly.

● Thickener in Liquid Medicines: Improves texture and stability in syrups, gels, and suspensions.

● Controlled Release Agent: Manages the release rate of active ingredients in sustained-release formulations.

● Thickener: Enhances viscosity and texture in shampoos, lotions, creams, and toothpaste.

● Film-Former: Creates a protective film on skin or hair in conditioners and styling gels.

● Stabilizer: Prevents ingredient separation in emulsions like creams and lotions.

● Textile Industry: Serves as a sizing agent and improves the viscosity of textile printing pastes.

● Paper Industry: Acts as a binder and surface treatment agent to improve paper quality.

● Ceramics: Functions as a binder and plasticizer, improving the workability of ceramic masses.

● Adhesives: Enhances viscosity and binding properties, especially in wallpaper paste.

● Drilling Fluids: Modifies viscosity and retains water in drilling fluids, improving efficiency and reducing fluid loss.

● Fracturing Fluids: Aids in the preparation of fracturing fluids used in hydraulic fracturing to extract oil and gas.

● Thickener: Improves viscosity and stability in liquid detergents and cleaning solutions.

● Stabilizer: Maintains formulation stability and prevents ingredient separation.

● Paints and Coatings: Serves as a thickener and stabilizer in water-based paints and coatings.

● Agriculture: Used in seed coatings and as a soil conditioner to enhance water retention and seed germination.

Properties and Applications of CMC

CMC is the sodium salt of cellulose carboxymethyl ether, an anionic cellulose ether. CMC is white or milky white fibrous powder or granules with a density of 0.5-0.7 g/cm3, almost odorless, tasteless, and hygroscopic. It is easy to disperse into a transparent gel solution in water, but insoluble in organic solvents such as ethanol.

Unraveling the Distinctions Between CMC and HEC

In the vast landscape of industrial chemicals, two cellulose derivatives stand out for their versatility and wide-ranging applications: Carboxymethyl Cellulose (CMC) and Hydroxyethyl Cellulose (HEC). Understanding the differences between these compounds is essential for industries ranging from food and pharmaceuticals to paints and personal care.

LEAVE A MESSAGE

Shijiazhuang Henggu Jianxin Cellulose Co., Ltd.

Chemical Industrial Park, Xinji City, Hebei Province, China Post Code: 052360

Copyright 2023 Shijiazhuang Henggu Jianxin Cellulose Co., Ltd. All Rights Reserved